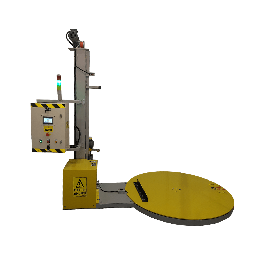

Semi Automatic Stretch Transfer Machine

Advantages

– Lower Stretch Cost

– Lower recycling cost

Options : Top Film Closing System

Advantages

– Protection the pallets from dust and other solid contaminants

– Protecting the paletts from water and liquid leaking from the top

– Savings from labor and materials by using nylon film instead of cardboard or plastic layer placed on pallet automatically

Options : Lasso Throwing System

Advantages

- Preventing overturning of items that can not be held in the pallet or intermediate card

– Saving from labor and materials by using stretch film instead of metal or plastic strap

Barcode – Squarecode Bonding & Reading Robot

Advantages

– Prevention of the labelling error

– Ensuring inventory tracking integration

– Ensuring automatic product traceability

– Ensuring labour savings

60 Pallets / Hour – Rotary Arm ( Mega Stretch Wrapping MgSS)

Advantages

– Standard stretch save (SSG) at 1×3 Ratio).

– Stretching without tilting the product with opening head with load control system (VLC)).

– Operatorless production (NNO) due to properoperation to synchronize with the line .

40 Pallets / Hour – Rotary Arm ( Jumbo Stretch Wrapping Jmss)

Advantages

– Standard stretch save (SSG) at 1×3 Ratio).

– Stretching without tilting the product with opening head with load control system (VLC)).

– Operatorless production (NNO) due to properoperation to synchronize with the line.

30 Pallet / Hour – Returning Conveyor (Rev Con Stretch Wrapping RxSS)

Advantages

– Standard stretch save (SSG) at 1×3 Ratio).

– Stretching without tilting the product with opening head with load control system (VLC)).

– Operatorless production (NNO) due to properoperation to synchronize with the line .

30 Pallets / Hour – Rotary Arm ( Maxi Stretch Wrapping MxSS)

Advantages

– Standard stretch save (SSG) at 1×3 Ratio).

– Stretching without tilting the product with opening head with load control system (VLC)).

– Operatorless production (NNO) due to properoperation to synchronize with the line .

20 Pallet/Hour – Returning Arm / Cold Room (COLD STRETCH WRAPPING CSS)

Advantages

– The design which can operate in 0: +5 C cold room

– Working with Pre-stressed stretch -Damage prevention via control system for uneven pallet (DPS)

– Damage prevention via control system for the dropped product (DPS)

– Cold chain storage system with manual top film covering system

20 Pallet / Hour – Returning Arm (Midi Stretch Wrapping MSS)

Advantages

– 1×3 standard stretch saving (SSG)

– load control system with prevention of tiltover for the pallet(VLC))

– Damage prevention with uneven pallet control system (DPS) – Damage prevention with per-item product control system (DPS)

20 Pallet / Hour-Return Table (Rev Stretch Wrapping RSS)

Advantages

– 1×3 standard stretch saving (SSG)

– load control system with prevention of tiltover for the pallet(VLC))